Table of Contents:

Table of Contents:

Watch the video:

What are Clean-In-Place Spaces?

Clean-in-place (CIP) rooms were first introduced in the 1950s and are designed for automated cleaning of interior equipment surfaces without requiring major disassembly[1]. These systems are integral to the operations of pharmaceutical and food & beverage facilities, providing a method to clean those hard-to-reach surfaces like pipes, vessels, equipment, and associated fittings. This process ensures thorough cleaning and sanitation, reduces downtime, and maintains high productivity.

CIP spaces are some of the most challenging areas in food & beverage and pharmaceutical facilities. Continuous chemical exposure from cleaning and sanitizing can wear down a floor that isn’t formulated for these extreme conditions.

What is the risk in CIP areas?

Floors in these environments are exposed to harsh, corrosive chemicals, frequent washdowns and heavy foot and equipment traffic. Unless formulated to withstand these extreme conditions, most flooring materials will deteriorate, eventually leading to cracks, contamination risks, and costly repairs.

Stonhard is in the business of solving tough problems for customers and has a new product designed specifically for these areas: Stonchem CIP.

What is Stonchem CIP?

Stonchem CIP is a workhorse system that is safe, long lasting, and will improve your CIP space with a seamless, clean design. Utilized globally, it ensures facilities operate more safely and efficiently.

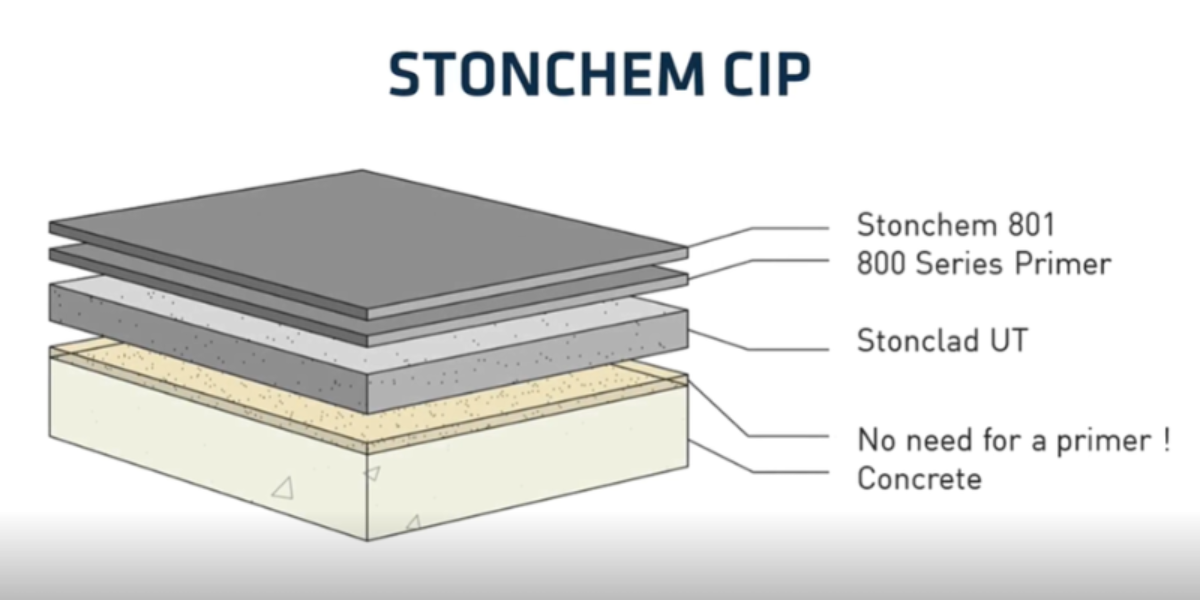

Stonchem CIP is comprised of the Stonchem 801 vinyl ester lining system, 800 series primer and Stonclad UT polyurethane mortar system.

We’ve merged our popular Stonclad UT urethane textured floor system known for its durability and resistance to traffic, impact, and thermal shock; with our Stonchem 800 series, a vinyl ester coating that effectively withstands CIP chemical attacks from nitric, phosphoric, peracetic acids, bleach, and caustics.

What does Stonchem CIP protect against?

Stonhard’s Stonchem CIP floor system is a champion for your facility, offering these features:

- Chemical resistance

- Thermal shock resistance

- Impact resistance

- Slip resistance

- High strength

- Seamless

What can a seamless floor do for my CIP area?

Implementing Stonchem CIP in your facility offers numerous benefits:

- Enhanced hygiene: The seamless, impervious surface helps maintain a sterile environment.

- Reduced downtime: The flooring's durability and ease of cleaning minimize maintenance-related downtime.

- Cost efficiency: Long-lasting performance translates to fewer repairs and replacements, saving money over time.

- Improved safety: Slip-resistant properties reduce the risk of workplace accidents.

- Regulatory compliance: Meets all necessary standards for hygiene and safety in pharmaceutical and food & beverage production.

How can I learn more about Stonchem CIP for my facility?

Contact your local Stonhard representative to get your questions answered about CIP flooring or any food and beverage flooring solution needs you have. Schedule your site visit today!

Related Articles

Loving this Content?

Subscribe to upcoming topics!

©2025 STONHARD. ALL RIGHTS RESERVED