High-Strength Flooring

Floors to resist compression and withstand heavy loads.

Tough floors for tough environments, built to last.

We've been in the business of formulating floors for manufacturing and warehouses for more than a century. We ensure your floor is strong enough to handle your heavy-duty environment, guaranteed.

What is High-Strength Flooring?

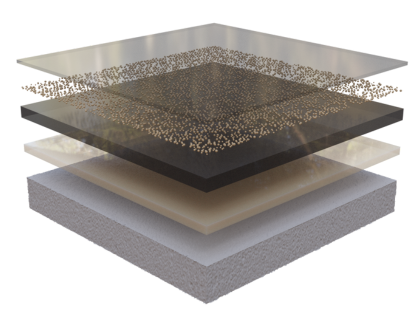

When it comes to floors, strength often relates to compressive strength – the capacity of a flooring material to withstand heavy loads and resist compression (density/materials being pressed together). Compressive strength looks at how much of a load a floor can handle and is usually reported in relationship to a specific technical standard. There are tests to ensure your floor will meet compressive-strength standards. The American Society for Testing and Materials is an international technical, scientific and education organization dedicated to the standardization of specifications and methods testing.

The Benefits of High-Strength Flooring

High-strength flooring offers many benefits, such as:

- standing up to the weight of heavy equipment and traffic

- saving time and money on floor repair and replacement due to failed or worn flooring

Explore a Project

Explore projects where high-strength flooring made all the difference. Dive into real-world examples where our expertise delivered flooring solutions built to last in the most demanding environments.

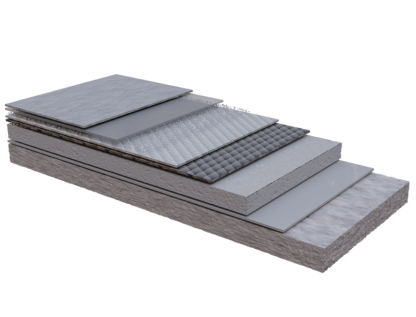

Recommended High-Strength Flooring

Stonhard formulates floors for every environment, including those requiring high-strength properties. Our team of Territory Managers, Architectural and Engineering Representatives will assist you in choosing the best product for your environment with the look you desire.

FAQ

Got questions? We've got answers. This FAQ section covers the most common inquiries about high-strength flooring to help you make informed decisions.

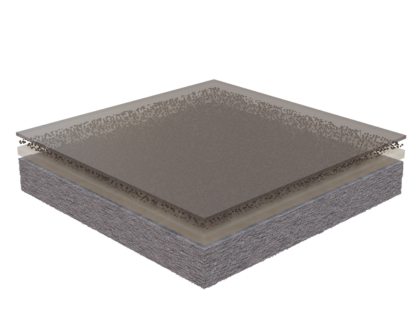

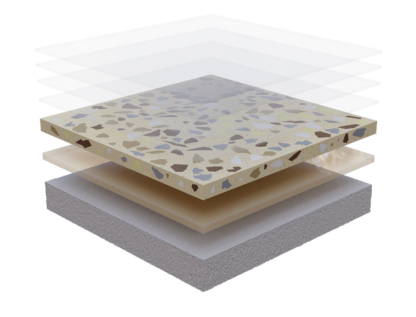

High-strength seamless floors are durable flooring systems typically made from epoxy or polyurethane resins. They are applied directly onto a substrate to create a continuous, smooth, and seamless surface.

- Durability: They are highly resistant to impact, abrasion, and chemicals.

- Hygiene: Seamless floors prevent bacteria buildup due to their non-porous nature.

- Aesthetic Appeal: They offer a smooth and attractive finish that can be customized with various colors and textures.

- Easy Maintenance: Cleaning is straightforward since there are no grout lines or seams where dirt can accumulate.

These floors are ideal for environments requiring robust flooring solutions, such as:

- Industrial Settings: Factories, warehouses, production areas.

- Commercial Spaces: Retail stores, hospitals, laboratories.

- Institutional Facilities: Schools, public restrooms.

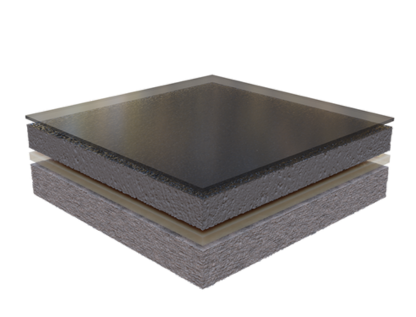

Installation involves several steps:

- Surface Preparation: Ensuring the substrate is clean and free of contaminants.

- Priming: Applying a primer to enhance adhesion.

- Application: Pouring or spreading the resin mixture evenly across the surface.

- Curing: Allowing sufficient time for the floor to cure and harden.

Routine cleaning with mild detergents and periodic inspections to address any wear or damage are typically sufficient. Depending on use and environment, periodic resealing or reapplication may be needed.

When properly installed and maintained, these floors can last 10-20 years or more, depending on the specific product and usage conditions.

Yes, additives can be incorporated into the resin during installation to enhance slip resistance, making them safe for various environments.

Consider factors such as the intended use (industrial, commercial, residential), specific environmental conditions (moisture, chemicals), aesthetic preferences, and budget. Consulting with a flooring expert can also provide valuable guidance.

Related Flooring Features

Expert Guides & Resources

Choosing the Right Floor For Your Facility

We know the commercial flooring market offers a vast array of optioned designed to meet your business's specific requirements and budget. Here we take a look at how two flooring types differ, exploring advantages and disadvantages.

Auto Manufacturing

Auto Manufacturing

Distribution & Logistics

Distribution & Logistics