Stonhard Floors Meet NASA’s Expectations for Cleanliness, Durability and Static Control

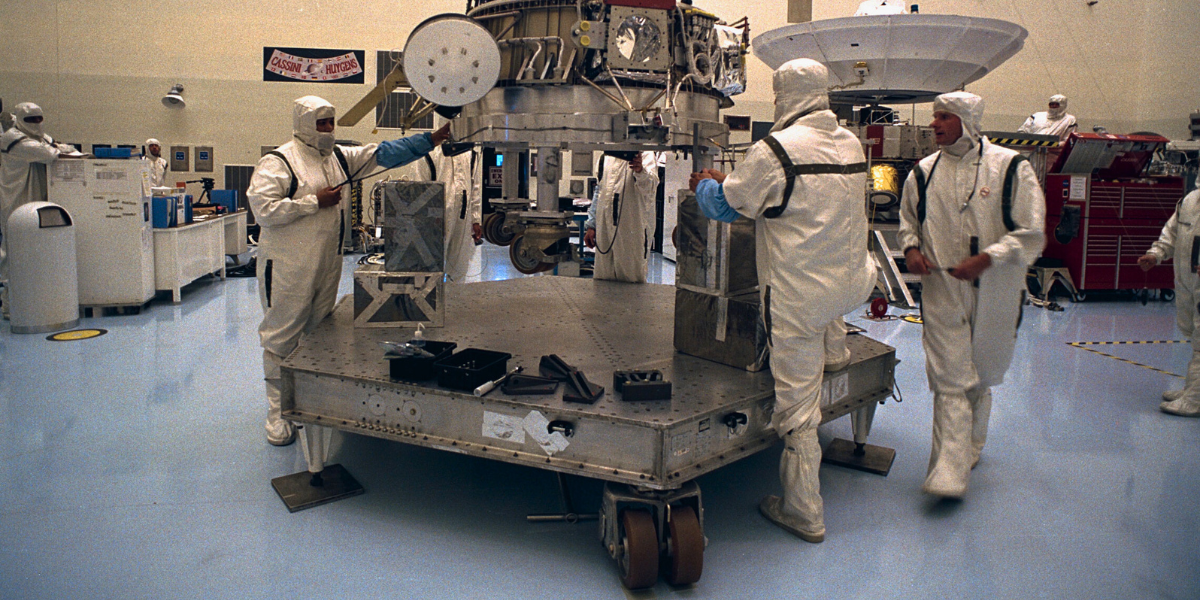

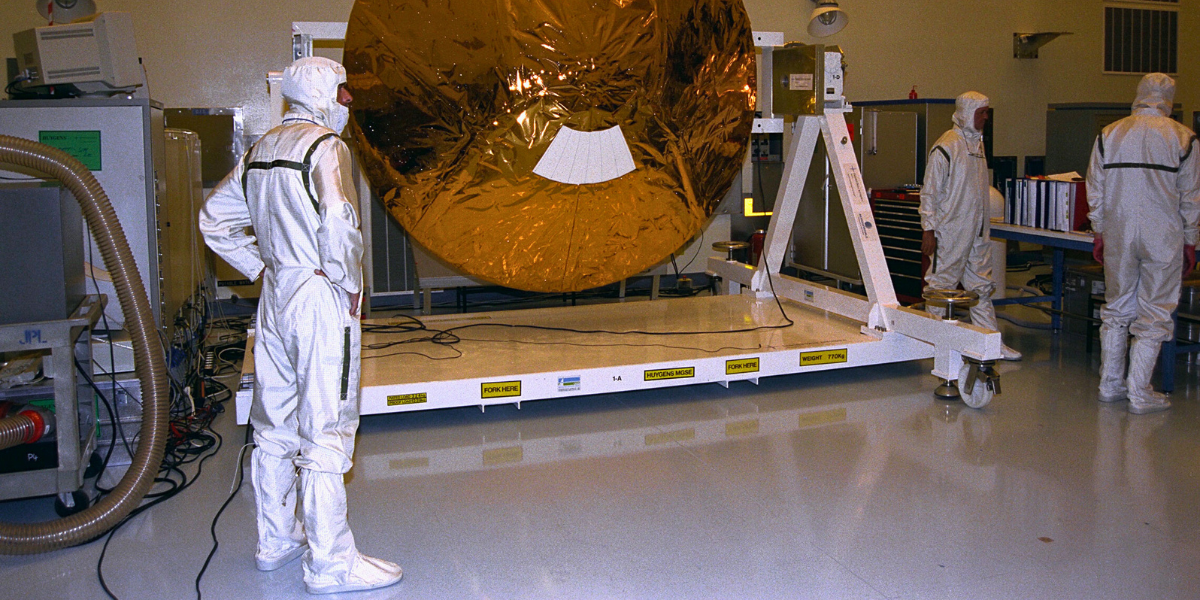

Stonhard crews successfully install a Stonlux ESD flooring system at NASA's Kennedy Space Center laboratory.

Seamless floors for aerospace facilities provide a clean, safe, and efficient workspace for cutting-edge technology and meticulous craftsmanship.

A Durable, Epoxy Flooring Solution to Control Static Electricity

In Cape Canaveral, Florida, NASA operates its Space Station Processing Facility (SSPF) out of the Kennedy Space Center. When more than 60,000 sq. ft. of vinyl tile disbanded eight months after its initial installation, the agency realized they needed a better flooring solution. The agency required strong and durable seamless floors that would meet clean manufacturing standards, stand up to the weight of heavy air pallets, and conduct static electricity to prevent electronic equipment damage and personnel injury. Stonhard’s Stonlux ESD epoxy flooring system was the perfect solution to meet NASA’s needs.

Stonhard ESD flooring protects people and components against electro-static discharge in aerospace processing facilities.

In addition to anti-static properties, Stonlux ESD provides exceptional durability, chemical resistance, as well as easy cleaning and maintenance for this NASA facility.

An ESD Flooring Solution That Offers Safety and Performance

Before installation, Stonhard crews eliminated osmotic pressure from the bare concrete using the pressure-resistant grout Stonfil OP2. Two separate primers were subsequently applied for floor-slab adhesion, and grounding plates were set into the second layer of conductive primer to provide a controlled ground point.

The Stonlux ESD floor was installed followed by a final step – testing the floor for electrical resistance and static generation. The new conductive floor passed each test with the highest grades. The material was found to be completely spark proof and safe for explosive applications.The electrical resistance of the floor was not only within standard, but also displayed a consistency that had not been achieved with ESD tile.

The electrical resistance consistency, coupled with the floor’s exceptionally low-body-voltage generation values, provided a Class 0 sensitivity safe environment. Agency staff were delighted with their new floors and welcomed Stonhard for further facility projects.

Loving This Content ?

Subscribe to get alerts about future projects and news!